The friction materials used by R Brake in the manufacturing of brake pads for industrial vehicles and lorries are made up of the most advanced raw materials, fibres, and lubricants, reinforced with the use of 2 pre-mixtures to create a dual matrix, which:

- Ensures optimum results in terms of performance, noise, and safety.

- Considerably reduces maintenance costs of the vehicle

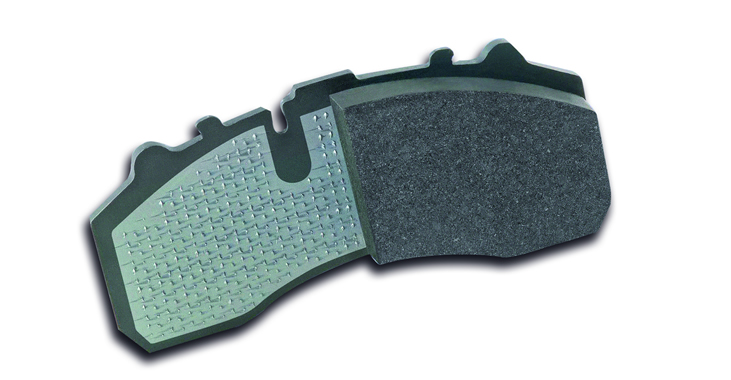

In addition to this, the NRS retaining system provides the following advantages:

- Increases shear resistance to more than 450 Newton / cm², with 100% adherence of the friction material to the metal support, exceeding the values demanded in today’s market.

- Improves thermal conductivity by more than 18%, dissipating (through the support) more of the heat generated on the friction surface. Extends the life of the brake pads and discs, reducing the appearance of cracks and microfissures.

- Increases the contact area between the friction material and the metal support by between 2 and 2.5 times, because the effect is three dimensional.

By implementing the strictest quality control systems, R Brake’s brake discs give customers better performance in all weather conditions. Whether on the “Rossfeld” alpine descent or on a slippery motorway, R Brake’s brake pads guarantee safety.